What if your factory’s data could generate as much revenue as your products? That’s possible through data monetization in manufacturing. Every production cycle, equipment reading, and supply chain transaction holds untapped potential to drive efficiency, profitability, and entirely new business opportunities. According to McKinsey, organizations that effectively monetize their data are three times more likely to see it contribute to over 20% of their total revenue.

Leading manufacturers are not just using data to optimize production; they are building data-driven businesses. They are offering digital services, building new business models, and collaborating with peers through shared data ecosystems. Snowflake AI Data Cloud helps to unify, analyze, and securely share data across the value chain, transforming raw information into a measurable business impact.

This blog explores how manufacturers can identify, structure, and scale their data monetization journey using Snowflake, while highlighting the key strategies and challenges in it.

Understanding Manufacturing Data Monetization

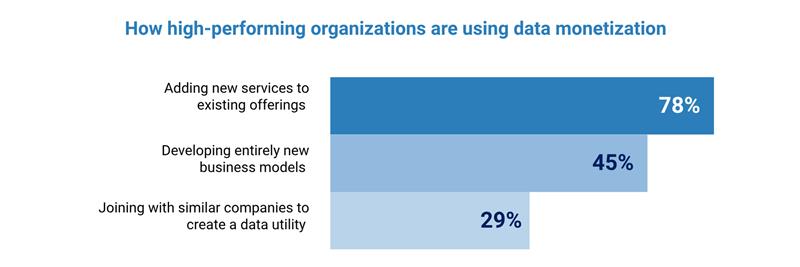

Manufacturing data monetization is the practice of turning the vast amounts of operational, production, and product data generated across the manufacturing ecosystem into measurable business value and gaining economic benefits. Every sensor reading, production log, and supply chain transaction has insights that can boost efficiency, innovation, and profitability.

Source: McKinsey

Data Monetization in Manufacturing Takes Two Main Forms

Indirect Monetization

Manufacturers use data internally to improve and streamline existing business operations and products. It enhances their own operations, reduces costs, and makes smarter decisions. Analyzing production data helps companies predict equipment failures, minimize downtime, optimize energy consumption, and improve product quality. This internal use of data doesn’t generate revenue directly but creates substantial value by improving efficiency, reducing waste, and increasing throughput.

Direct Monetization

This type creates new revenue streams by selling data-driven products or services to external parties. This could mean offering data-driven services (like predictive maintenance for customers), providing supply chain visibility to partners, or developing usage-based product models powered by IoT data. In this model, data itself becomes a product, driving new revenue streams and strengthening customer relationships.

How to Monetize Your Manufacturing Data?

Sell Raw Data

Manufacturers generate massive amounts of raw data. It consists of information about equipment performance, energy usage, production throughput, and material efficiency. This raw, anonymized data can hold immense value for other players like suppliers, technology vendors, and research institutions. For example, a car parts manufacturer sells anonymized machine performance data to an equipment supplier, helping them improve their machine design and durability. Selling these curated data sets helps in product innovation and market research.

Data-Driven Service (Servitization)

Servitization is one of the most transformative approaches to monetizing data. Instead of just selling physical products, manufacturers integrate data and digital services into their offerings to create new, recurring revenue streams. Using IoT and AI, they can monitor equipment condition, predict maintenance needs, and offer performance-based contracts or “as-a-service” models. This approach improves customer relationships and increases long-term profitability.

Partnerships and Data Sharing

Manufacturers can create mutual value by securely sharing data with their partners, suppliers, distributors, or logistics providers. Data sharing improves supply chain transparency, enhances accuracy, and supports co-innovation initiatives. Through governed data-sharing platforms like Snowflake, manufacturers can enable data security.

Contributing Data to AI Development

High-quality industrial data is vital for training artificial intelligence and machine learning models. Manufacturers can collaborate with AI companies or research organizations, contributing datasets that help develop new algorithms, predictive tools, or automation technologies. This results in licensing revenue, joint intellectual property, or co-developed AI solutions that enhance efficiency and innovation.

Creating Data Marketplaces or Exchanges

One of the emerging trends in data monetization is establishing or participating in data marketplaces, platforms where organizations can trade or share data securely. Manufacturers can list their datasets and earn revenue through subscription or usage-based models. These marketplaces make it easier to reach a broader audience of data consumers, ranging from R&D organizations to analytics firms. This provides full control over access and usage of rights.

Key Challenges in Monetizing Manufacturing Data

Technical and Data Challenges

Manufacturers generate enormous amounts of data from multiple sources, like IoT sensors, production equipment, ERP systems, and supply chain networks. It is not an easy task to manage and extract potential insights from them.

Data Silos: Manufacturing operations often span multiple plants, each using distinct systems and formats. This creates fragmented data silos, making it difficult to gain a unified, real-time view of performance.

Data Quality and advanced tools: Raw industrial data can be incomplete, inconsistent, or unstructured. Without proper cleansing and governance, these data inconsistencies affect analytics’ accuracy and reduce trust in the outcomes. Deriving actionable insights often involves AI, ML, and predictive modeling, which requires specialized tools and expertise.

Lack of Infrastructure: Legacy, on-premises systems are not built to handle the scale, speed, and variety of modern manufacturing data. Monetization requires cloud-based, scalable infrastructure that supports real-time processing, data sharing, and advanced analytics.

Business and Organizational Challenges

Business and Organizational Challenges

Data monetization is a strategic transformation. Many manufacturers face internal barriers that hinder their ability to operationalize and scale data-driven value.

Clear Strategy: Many organizations collect data but lack a strategy for using it or for turning it into measurable business outcomes. Without defined goals, ROI metrics, and ownership, monetization efforts often remain fragmented.

Cultural Resistance: Manufacturing teams are often production-focused and may view data initiatives as secondary to core operations. This resistance slows adoption and limits innovation. Upskilling and change management have become essential.

Cross-Functional management: Successful monetization requires collaboration across IT, operations, product, and business teams. Misalignment among these units often results in disconnected efforts and missed opportunities.

Legal and Ethical Considerations

As data becomes a monetizable asset, manufacturers must adopt complex legal and ethical policies to ensure responsible and compliant use.

Data Privacy: Manufacturing data contains crucial information about operations, suppliers, and customers. Regulations like GDPR, CCPA, and regional data protection laws impose strict rules on how this data can be used and shared.

Intellectual Property and Ownership: As it involves partners, suppliers, or end users, it is important to determine who owns the data. Clear data ownership policies are essential before monetization can occur.

Security Risks: Monetization often involves sharing or exchanging data with third parties, increasing exposure to cyber threats. Without robust data governance and access controls, manufacturers risk data leaks or misuse.

Ethical Data Usage: Using data responsibly is just as important as using it profitably. Ethical concerns arise when data sharing or analytics could inadvertently expose sensitive insights about workers, customers, or partners.

How Manufacturers Can Monetize Data with Snowflake?

The Snowflake AI Data Cloud empowers manufacturers to identify the value of their operational, production, and supply chain data. Manufacturers can transform raw information into actionable insights effectively using Snowflake. Here’s how they do it:

Predictive Maintenance

Snowflake helps to easily integrate IoT sensor data, maintenance logs, and performance metrics into a unified data platform. Using AI-driven analytics, manufacturers can predict equipment failures and avoid them, reducing downtime and maintenance costs. This enhances productivity and offers predictive maintenance services to customers as a premium value-add.

Smart Supply Chain Management

With Snowflake’s secure data-sharing capabilities, manufacturers can provide partners, suppliers, and distributors with real-time visibility into inventory levels, production timelines, and logistics. This transparency helps optimize the entire supply chain system to reduce bottlenecks and enable partners to make data-driven decisions without data duplication.

Product-as-a-Service (PaaS) Models

Manufacturers are increasingly shifting from one-time product sales to data-enabled service models, where usage data from connected products is analyzed to offer performance-based contracts or subscription pricing. Snowflake’s scalable data platform makes it possible to manage large volumes of usage data securely, supporting servitization and recurring revenue models.

Personalize Customer Experience

Data from connected products, service interactions, and sales channels can be unified in Snowflake to deliver deeper insights into customer behavior. Manufacturers can use this data to offer personalized product recommendations, optimize after-sales support, and enhance customer satisfaction.

Strategies for Monetizing Manufacturing Data with Snowflake

Monetizing manufacturing data requires a structured approach, from identifying valuable raw data to enriching it for insights and enabling secure collaboration. Below are the key strategies to implement.

Raw Data

One of the simplest ways to monetize manufacturing data is by sharing raw, non-sensitive datasets with all Personally Identifiable Information (PII) removed and presenting them on Snowflake marketplace. This allows other organizations to use your production, supply chain, or equipment data for their own analytics, benchmarking, or AI model development, turning unused data into a new revenue stream.

Identify Monetization Opportunities

Manufacturers can create value from data by identifying different opportunities. One key avenue is operational improvements; real-time analytics enhance efficiency, reduce downtime, and cut costs. Another one is data-as-a-service, securely sharing or selling curated insights to partners using Snowflake. Also, manufacturers can think of product enhancements, using data to refine designs and improve performance.

Enriched Your Data

Raw data alone is valuable, but its true potential emerges when it’s enriched, contextualized, and analyzed. Manufacturers can analyze and transform data to offer pre-processed, insight-ready datasets. This approach is appealing to buyers and makes enriched data a premium monetization opportunity on Snowflake Marketplace

Data Clean Rooms

One of Snowflake’s most powerful capabilities is the Data Clean Room, a secure and privacy-preserving environment. Through clean rooms, manufacturers can collaborate and share data insights with partners, OEMs (Original Equipment Manufacturers), or distributors safely, ensuring compliance and data confidentiality.

Conclusion

As manufacturers move toward becoming data-driven enterprises, the ability to monetize data effectively is emerging as a critical differentiator. Using platforms like Snowflake, manufacturers can identify new business value, whether through operational efficiencies, smart supply chain visibility, or entirely new data-driven services. But successful data monetization requires more than just access to data; it demands the right architecture, governance, and strategic execution. That’s where Kasmo helps businesses. As a trusted Snowflake partner, Kasmo enables manufacturers to identify the value of their data by designing scalable, secure, and AI-ready data foundations.