Manufacturing is an important part of industrial growth, but it comes with challenges. Unexpected downtimes, equipment failures, or increasing repair costs often disrupt production efficiencies, resulting in potential financial losses. To stay ahead, manufacturers are increasingly turning to predictive maintenance powered by AI.

Predictive maintenance is proactive, leveraging varying technologies such as Artificial Intelligence (AI), computer vision, data analytics, and a variety of machine learning algorithms to continuously monitor the condition of your equipment in real-time. Manufacturing predictive maintenance is a strategic approach to help industries predict and prevent equipment failures to allow them to improve operational efficiencies. The Deloitte smart manufacturing survey reports up to 20% improvement in production output, 20% in employee productivity, and 15% in unlocked capacity.

Predictive maintenance goes beyond traditional reactive or scheduled maintenance strategies. From anomaly detection to predict failures and proactively maintain assets, predictive maintenance is crucial in manufacturing. It is flexible and cost-effective, helping companies to prevent losses and enhance efficiencies. More importantly, predictive maintenance helps manufacturers build resilience, stay competitive, and deliver consistent product quality in a fast-moving market.

What is Predictive Maintenance in Manufacturing?

Predictive maintenance (PdM) in manufacturing is a proactive approach that uses advanced technologies like IoT sensors, machine learning, and data analytics to monitor the overall process. Predictive maintenance relies on real-time data and predictive models to determine the optimal time for maintenance. It works by emphasizing the role of data collection from visual data and the use of machine learning and AI techniques to predict machinery failures, minimize unplanned downtime, reduce maintenance costs, and ensure smoother, more efficient production processes.

How Predictive Maintenance for Manufacturing Works?

Predictive Maintenance integrates multiple technologies, like AI, ML, Internet of Things (IoT), and predictive analytics. PdM systems functions include:

The first step in this process involves the collection of real-time data and information from sensors, such as sound, vibration, and temperature of the manufacturing equipment.

Next, this data is then transmitted to a central platform, where AI and machine learning models process it to detect patterns, anomalies, or deviations from normal operating conditions.

Data-driven processes generate alerts or maintenance recommendations, allowing technicians to address problems before they lead to breakdowns. It enables timely adjustments and delivers orders with increased efficiency.

Hence, the predictive maintenance cycle of data collection, analysis, prediction, and action helps manufacturers to reduce downtime, optimize maintenance schedules, and extend the lifespan of their assets.

Role of Salesforce Agentforce in Smart Manufacturing

Salesforce Agentforce is an intelligent AI-powered agent to perform tasks, make data-driven decisions, and drive business outcomes autonomously, with minimal human intervention. Leveraging Salesforce’s data ecosystem, machine learning models, and real-time analytics, these agents can enhance customer engagement, automate workflows, optimize sales and service processes, and deliver personalized experiences at scale.

In manufacturing, AI agents help to improve production by automating multiple processes. Manufacturers can optimize scheduling, streamline inventory, predict the need for raw materials, support quality, etc. AI agents are ideal in a manufacturing context due to their ability to process large volumes of data, recognize emergent patterns from the data or its feedback in a real-time environment, and more. This helps businesses to achieve higher levels of efficiency and productivity.

Use Cases of Agentforce in Manufacturing

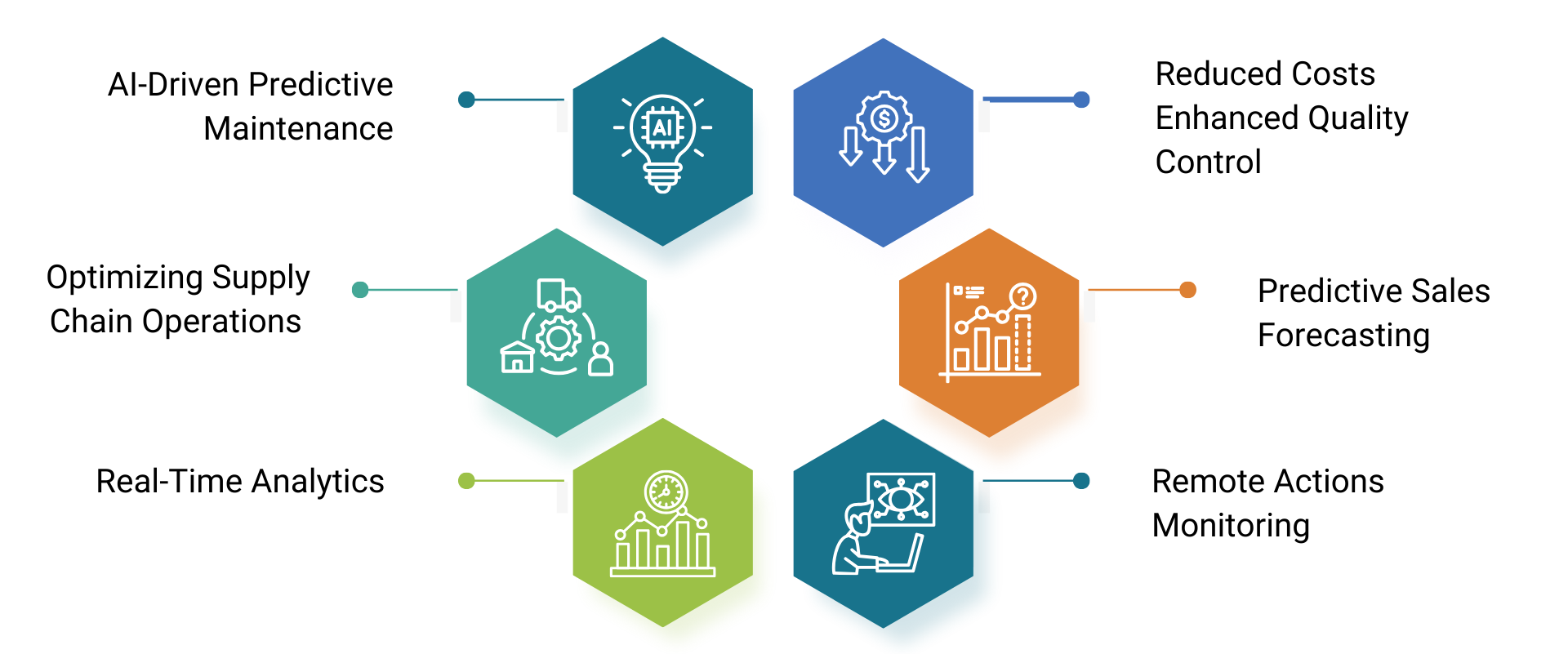

AI-Driven Predictive Maintenance

Malfunction of equipment leads to delays and production inefficiencies. Agentforce uses artificial intelligence to monitor tool performance and predict maintenance timing to avoid breakdowns and reduce downtime. AI agents analyze historical maintenance records, sensor data, and production schedules to avoid potential equipment failures and maximize uptime.

Optimizing Supply Chain Operations

Supply chain management is a core component of manufacturing and can be managed efficiently using Agentforce. Using AI helps to optimize supply chain processes and ensure the timely delivery of raw materials and efficient distribution of goods. Companies using Agentforce can easily track inventory levels, supplier lead times, and shipping schedules. Predicts shortages and suggests optimal ordering times to meet production schedules and minimize supply chain disruptions. This enables manufacturers to meet customers’ demands by enhancing productivity.

Real-Time Analytics

Gaining real-time analytics about production lines from Agentforce, manufacturers can identify bottlenecks and manage workflow. AI and data-driven insight improve production efficiency and minimize waste. Agentforce provides the ability to accurately track KPI’s like speed, quality assurance, production size, and defects. This helps to optimize production, reduce waste, and deliver better outcomes.

Reduced Costs Through Automation

Integration with Agentforce allows manufacturers to reduce costs and streamline processes. Predictive maintenance solutions help to reduce unplanned downtime. AI optimizes the supply chain, will help to minimize waste and inefficiencies, and will again help manufacturers to gain better cost control and margin improvement.

Enhanced Quality Control

Quality control is one of the most important aspects of manufacturing and is the key to customer retention. Agentforce uses AI to monitor quality control processes, detect defects during production, and make recommendations on production settings to help manufacturers take actions to ensure that products meet stipulated industry standards and deliver consistent product quality.

Predictive Sales Forecasting

Agentforce provides an AI-driven predictive analytics capacity that can forecast sales and product demand. Agentforce uses historical sales order data to analyze market conditions and customer behavior to predict accurate sales demand.

Remote Monitoring

AI agents are able to remotely manage physical assets, including changing production rates or re-ordering materials, using decisions made through data analysis and predictive models. This eliminates the need for human intervention and allows quicker adoption to avoid delays. Gaining continuous updates and automated responses helps manufacturers enhance business operations and provide rapid responses to unexpected challenges in supply or demand. This enables greater productivity with fewer errors.

The Future of Agentforce in Manufacturing

Advanced AI-Driven Innovation

Agentforce is expected to deliver more than just automated administrative functions. Advanced AI agents will eventually be capable of executing more complex, cross-functional processes with lower human intervention. For instance, in manufacturing, intelligent agents can manage end-to-end supply chain orchestration covering order tracking to distribution and evolve with changing needs.

Deeper Integration with IIoT

As manufacturers leverage IIoT (Industrial Internet of Things) systems to incorporate machine sensors and smart devices into their day-to-day operations, Agentforce helps to analyze vast amounts of real-time data. Future AI agents will make instantaneous decisions to change production lines, quality assurance, and prevent issues before they occur.

Collaboration with Emerging Technologies

Agentforce evolves and will likely be integrated with advanced technologies like blockchain and augmented reality (AR) in the real-time manufacturing stream. AI agents may run alongside a digital twin representation of a manufacturing plant to identify and simulate multiple production scenarios, check efficiencies, and optimize processes.

Al-Driven Sustainability Initiatives

Manufacturing firms are increasingly prioritizing sustainability. Future versions of Agentforce, supported by Salesforce managed services, are expected to integrate sustainability metrics into operational decisions. AI agents could help reduce wastage, optimize energy usage, and ensure that all processes are as eco-friendly as possible. By analyzing data from every stage of production, AI agents can provide real-time recommendations on how to reduce carbon footprints and energy consumption.

Conclusion

Predictive maintenance is a competitive necessity for modern manufacturers. It helps reduce downtime, improve accuracy, and achieve great cost savings. By anticipating issues before they occur, manufacturers can shift from reactive to proactive operations, ensuring efficiency and reliability across the production lifecycle. As the manufacturing sector becomes increasingly complex, leveraging a modern approach is essential for growth.

Integrating Salesforce Agentforce into your manufacturing strategy takes predictive maintenance a step further, enabling intelligent, automated interactions that streamline issue resolution, enhance visibility, and empower teams with actionable insights. Agentforce creates a powerful foundation for smarter operations, stronger customer trust, and sustainable growth in the manufacturing sector. For manufacturers ready to embrace the future, Salesforce’s Agentforce and Kasmo’s expertise help you with business-centric, scalable, and secure solutions.