What is Manufacturing BOM?

A manufacturing bill of materials (mBOM), often referred to as manufacturing BOM, is a detailed, structured list of all the parts, sub-assemblies, raw materials, and processes required to manufacture a finished product. A BOM is a key input for production planning and inventory management. It acts as a connecting source between product design and production, ensuring that every component is identified, sourced, and assembled correctly. It also describes the amount of material that needs to be used, the progression, and other supportive data for smart manufacturing.

A BOM is necessary to ensure smooth and efficient manufacturing task completion at a fixed cost. It assists firms in tracking inventory, minimizing shortages, and meeting quality and design specifications in assembling products. The BOM manages the progress of operations, purchasing, and logistics of the product. The BOM is then sent to business systems and used by enterprise resource planning (ERP) systems and manufacturing execution systems (MES).

Benefits of Using a Manufacturing BOM

The BOM helps manufacturing with accurate tracking of components and assemblies to enhance visibility and increase production accuracy. The major benefits of manufacturing BOM include:

Increase Manufacturing Efficiency: The bill of materials in manufacturing accomplishes precise assembly instructions for manufacturing teams to prevent mismatches between design and production.

Reduces Production Errors: The bill of materials provides assembly instructions including several quality checkpoints and specifications, which minimize the chance of errors such as wrong part installations or process.

Product Customization: BOMs drive flexible manufacturing options to meet real-time customer requirements or change extrinsic market influence without affecting the workflow.

Challenges in BOM Management

Technology Integration

Data silos in Product Lifecycle Management and Enterprise Resource Planning cause misalignment of workflow in the manufacturing process. More explicitly, the planning of tooling requirements or work instructions provided in the BOM will not link with schedules found in the ERP. This leads to delays and inefficiencies.

Affects Post-lead Conversion

Inaccurate BOMs lead to inaccuracies, inconsistencies, or incompleteness in the production process, which results in increased costs and errors. These errors have an influence on a customer’s decision to discontinue or confirm orders.

Supply Chain Disruptions

According to the Salesforce Trends in Manufacturing Report, “67% of manufacturers have experienced supply chain disruptions since 2020, and 59% say these persist to some degree today”. Materials shortages increase supplier volatility, presenting a need for agile BOM adjustments. Wrong product information, like name, number, or model, leads to production halts. Hence, manufacturers require frequent updates to BOMs to shift direction to alternative materials or suppliers without jeopardizing quality.

Maintaining Multi-level BOMs

When managing hierarchical systems of interdependent components, subassemblies, and processes, multi-level BOMs are challenging for manufacturers. This can be effectively solved by integrating a centralized system, which mitigates errors associated with incorrect subassemblies and excess production of raw materials.

Salesforce Manufacturing Cloud for Effective BOM Management

Salesforce Manufacturing Cloud is an effective solution to overcome these challenges and drive manufacturing success. This cloud is a centralized, cloud-based system intended for the manufacturing industry to streamline workflow, integrate opportunities, connect with suppliers, demand forecasts, and improve overall production.

- The platform creates a cohesive connection point for your sales and product data, allowing manufacturers to create and administer Bills of Materials seamlessly and effortlessly in a connected digital space.

- By connecting Salesforce’s Sales Cloud directly to the Bill of Materials (BOM), manufacturers can determine the right quantities of components needed, reducing risks of over- or under-production

- Provides insight into pricing, cost, and margins related to BOM components. It tracks updates in the Engineering BOM (EBOM) and the Manufacturing BOM (MBOM), helping manufacturers with accurate cost estimation, controlling efficiency, and avoiding financial losses.

- By managing BOM data within Salesforce’s centralized platform, sales, operations, and production teams can always access the latest and most accurate BOM version.

Kasmo’s BOM 360 Accelerator for Manufacturing

Kasmo’s BOM 360 is an intelligent, end-to-end Bill of Materials (BOM) management solution built on Salesforce. It centralizes and streamlines the entire BOM calculation process, ensuring that Procurement, Logistics, Manufacturing Operations, Finance, and Sales all work with the same source of truth. This cross-functional integration eliminates silos, reduces errors, and allows every stakeholder to contribute accurate inputs to enhance business growth.

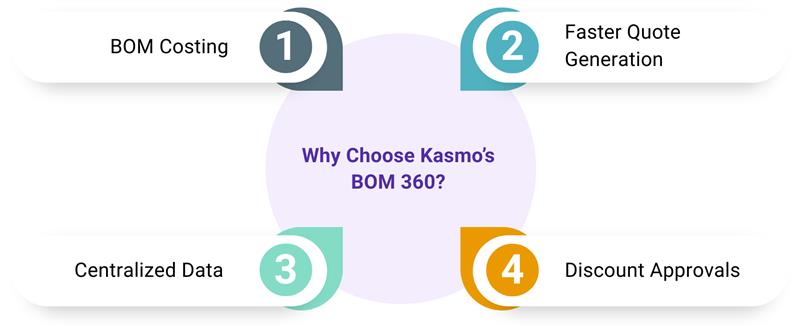

Why Choose Kasmo’s BOM 360?

BOM Costing

BOM 360 automatically calculates true product costs across all functions, reducing manual effort and minimizing pricing risks. Teams gain instant visibility into component costs, labor, logistics, and overheads—ensuring accurate cost models for every product configuration.

Faster Quote Generation

With automated cost calculations and pre-approved pricing logic, BOM 360 enables Sales teams to generate quotes faster and with greater confidence. This leads to shorter sales cycles, improved conversion rates, and enhanced services.

Centralized Data

All product cost data is centralized within the Salesforce ecosystem, eliminating version conflicts and ensuring every team works with updated and accurate information. This helps with data-driven insights for faster and smarter decision-making.

Discount Approvals

The accelerator provides Finance and Sales leaders with margin visibility and EBITA insights, ensuring that discount approvals are based on profitability. This helps protect margins and drive better revenue outcomes.

Conclusion

An accurate and well-managed Manufacturing Bill of Materials is critical for manufacturing success as it ensures efficiency, cost control, and product quality. BOM management comes with challenges that will hinder production and customer satisfaction. Salesforce Manufacturing Cloud stands out by connecting BOM data to demand forecasting and customer needs for customization, inventory management, cost-effectiveness, and more. It adds significant value in the manufacturing process to meet customer demand, deliver quality products, and drive business success.

Kasmo’s BOM 360 Accelerator empowers manufacturers to manage product costing by bringing accuracy, speed, and collaboration into a single Salesforce-powered solution. With accurate real-time BOM calculations, automated quoting, and profitability-driven insights, it helps manufacturing eliminate manual errors and scale faster.