Introduction

A single raw-material shortage at one pharma plant can halt production, while the same material sits unused at another facility. For supply chain operations managers, this imbalance is a daily reality, made worse by fragmented data, manual analysis, and decisions that must be made faster than traditional planning tools allow. Traditional AI and analytics can surface insights, but they still depend heavily on human intervention to interpret data and decide what actions to take, slowing response times.

Agentic AI changes this equation by moving supply chain management in pharma from insight-driven to action-driven operations. Instead of relying on human-led interpretation, agentic AI systems continuously monitor demand signals, inventory positions, supplier performance, and more. Later, it also plans, executes, and refines decisions in real time. As autonomous supply chain agents gain traction in 2026, pharma manufacturers are adopting intelligent assistants powered by Snowflake Intelligence and Cortex AI to rebalance inventory, optimize production, and respond to disruptions. The result is a more resilient, responsive supply chain designed to protect both operations and patient outcomes.

In this blog, we explore how agentic AI is enhancing the pharma manufacturing supply chain by turning real-time data into intelligent, governed actions using Snowflake.

What Is Agentic AI in Pharma Supply Chain Management?

Agentic AI for supply chain management in pharma refers to intelligent systems that can independently analyze data, make decisions, and take action across the supply network. Traditional AI methods can generate insights, while agentic AI can actively decide the next actions. In a pharma context, this means continuously monitoring demand signals, inventory positions, and supplier performance, to adjust plans without manual intervention.

What makes agentic AI uniquely suited for pharma supply chains is its ability to operate within high-stakes, constraint-heavy environments. Drug manufacturing involves shelf-life limits, batch traceability, cold-chain dependencies, strict compliance, and more. Agentic AI systems can factor in these realities while making real-time decisions. It can handle reallocating inventory across regions, adjusting production schedules, or prioritizing high-impact SKUs during shortages, all using the given data.

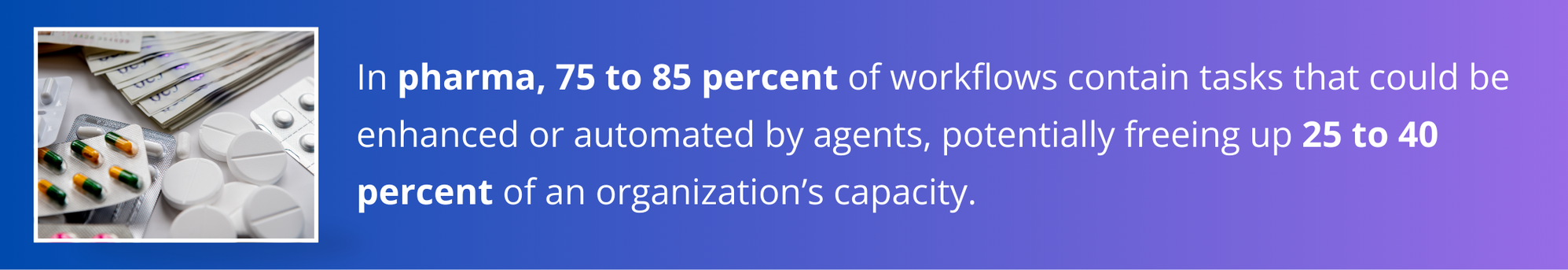

Source: McKinsey

The Rise of Autonomous Supply Chain Agents in 2026

In 2026, pharma manufacturers are adopting agentic AI in supply chain that plans, executes, and iterates. Earlier AI deployments focused on dashboards, alerts, or chat-based interfaces that surfaced insights but left execution to humans. Autonomous supply chain agents translate insights into coordinated actions. This evolution is driven by the growing complexity of pharma manufacturing networks. Multi-tier suppliers, contract manufacturers, global distribution hubs, and variable regulatory environments.

The pace and complexity of disruptions will exceed human decision-making capacity. Shortage risks, geopolitical instability, and demand spikes require always-on intelligence that can act instantly. Autonomous supply chain agents are needed to maintain resilience, reduce response time, and protect patient outcomes without relying on constant human oversight.

How Snowflake Intelligence Enables Agentic AI for Supply Chain Management in Pharma

Data Foundation for Autonomous Agents

Agentic AI in pharma supply chains depends on a single, reliable source of truth. Snowflake Intelligence brings together data from ERP systems, MES (Manufacturing Execution System), LIMS (Laboratory Information Management System), quality systems, and distributors into one governed platform. This unified foundation allows AI agents to reason across the entire supply chain.

For pharma manufacturers, this helps, as decisions cannot be made in isolation. Inventory optimizations include batch genealogy, shelf life, and quality status. Snowflake’s ability to harmonize structured and semi-structured data helps AI agents to act on accurate, compliant, and contextualized information, reducing the risk of costly or non-compliant actions.

Respond to Supply Chain Disruptions

Pharma supply chains are highly sensitive to disruptions, API shortages, cold-chain failures, transportation delays, or sudden demand spikes. Snowflake Intelligence enables agentic AI systems to continuously predict changes as they occur, rather than relying on static reports.

This real-time intelligence allows autonomous agents to respond instantly. For example, rerouting inventory before a shortage occurs, prioritizing life-saving drugs during demand surges, or adjusting production schedules based on upstream supplier delays. In a pharma environment where delays directly impact patient outcomes, Snowflake’s real-time data processing becomes the backbone for always-on, responsive AI agents.

Secure and Governed Intelligence

Agentic AI must operate within strict regulatory boundaries in pharma manufacturing. Snowflake Intelligence enables enterprise-grade governance, security, and auditability, ensuring that autonomous decisions are transparent and compliant with GxP requirements.

This governance layer allows organizations to define what AI agents can access, recommend, or execute. Every action taken by an agent can be traced back to its data inputs and logic, which is essential for audits, reporting, and internal quality reviews.

Enabling Continuous Learning

Agentic AI is not static; it learns from outcomes. Snowflake supports this continuous learning loop by storing historical decisions, execution results, and performance metrics at scale. Over time, agents can evaluate strategies to reduce inventory shortages, improve forecasts, and minimize supplier decisions at risk.

For supply chain management in pharma, where variability is high and historical patterns matter, this feedback loop is invaluable. Snowflake enables agents to refine decision-making across multiple dimensions—cost, service level, compliance, and resilience—helping manufacturers evolve from reactive operations to self-optimizing supply networks.

Building a ‘Supply Chain Assistant’ with Cortex Analyst and Snowflake Intelligence

Supply chain managers deal with several challenges across manufacturing sites. While some plants sit on excess inventory, others struggle with shortages, leading to higher costs and supply chain disruptions. Relying on manual reports and spreadsheets slows decision-making and increases the risk of production delays. So, adopting an intelligent AI agent solves these problems and enables effective supply chain management. Building an agent using Snowflake requires-

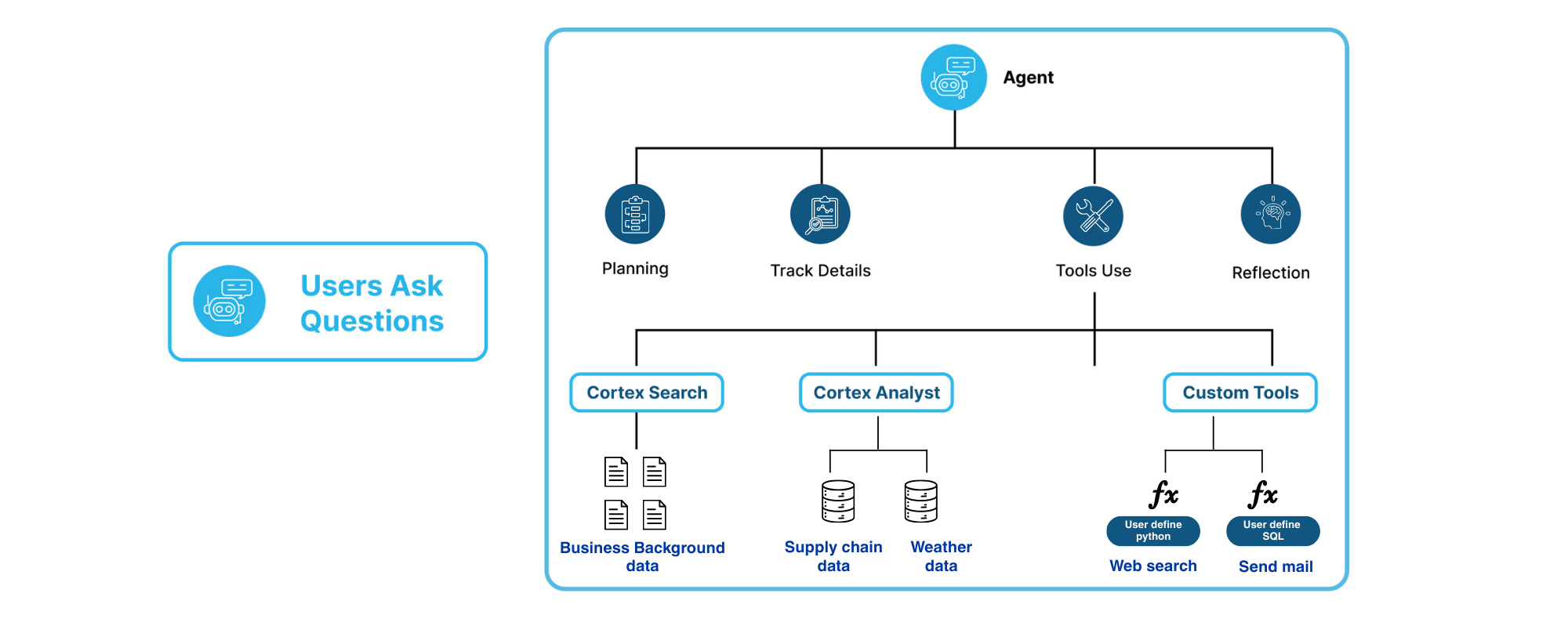

Snowflake Cortex- It provides fully managed Generative AI capabilities that run inside the Snowflake platform. Snowflake Cortex acts as the AI intelligence layer that sits directly on top of your structured and unstructured data. It enables AI-driven analysis, search, and interaction without requiring separate infrastructure.

Cortex Analyst- Allows business users to ask questions in plain language about structured data like inventory tables, order data, shipment records, or supplier costs. Instead of writing SQL queries or relying on analysts, users can simply ask questions like “Which plants are running low on critical materials?”

Cortex Search- It is designed to work with unstructured data, like supply chain documents, SOPs, contracts, policies, or logistics reports. It automatically handles document processing tasks like breaking files into chunks and retrieving the most relevant content.

Snowflake Intelligence- This provides a unified experience for building, deploying, and interacting with AI agents directly inside Snowflake. While Cortex provides individual AI capabilities, Snowflake Intelligence brings them together into a working system.

Supply Chain Agent Solution Working

This supply chain agent solution combines Snowflake Intelligence and Cortex AI to create an intelligent assistant for supply chain operations. The goal is to help teams make faster, better decisions, without technical complexity.

Answering Supply Chain Questions: Users can ask natural language questions about inventory levels, open orders, or shipment status. The agent automatically understands the question, converts it into SQL, and runs it on live data. This removes delays caused by manual reporting or analyst dependency and enables real-time decision-making.

Providing Contextual Information: Not all supply chain knowledge lives in tables. Policies, contracts, and operational guidelines are often stored as documents. The agent uses semantic search to get relevant information from these sources. This ensures decisions are informed by both data and documented business context.

Routing Between Data and Documents: The agent automatically decides how to answer a question. If the question requires numbers or calculations, it uses Cortex Analyst. If it requires policy or procedural knowledge, it uses Cortex Search.

Handling Supply Chain Analysis: The assistant can perform advanced analysis that spans multiple datasets, like identifying plants with low inventory while others have excess stock of the same material, or comparing supplier costs against inter-plant transfer costs.

No-Code Deployment: The entire supply chain agent, from data access to conversational interaction, can be built and deployed using Snowflake Intelligence’s no-code interface.

Conclusion

Supply chain management in pharma manufacturing becomes more advanced and moves beyond manual planning, static reports, or production risks. The shift toward agentic AI in supply chain operations involves sensing disruptions, making decisions, and acting in real time. Snowflake provides the secure platform required to operationalize this autonomy. With Snowflake Intelligence and Cortex capabilities, pharma manufacturers can unify data, enable trusted decision-making, and deploy agentic AI in the supply chain, while meeting strict regulatory and compliance requirements.

Kasmo helps pharma organizations adopt agentic solutions. As a Snowflake Premier partner with strong expertise in healthcare and AI-led analytics, Kasmo supports the full implementation journey. From data foundation and semantic modeling to deploying and scaling agentic services on Snowflake. With Kasmo, pharma manufacturers can reduce implementation complexity and build resilient, autonomous AI agents for long-term impact.